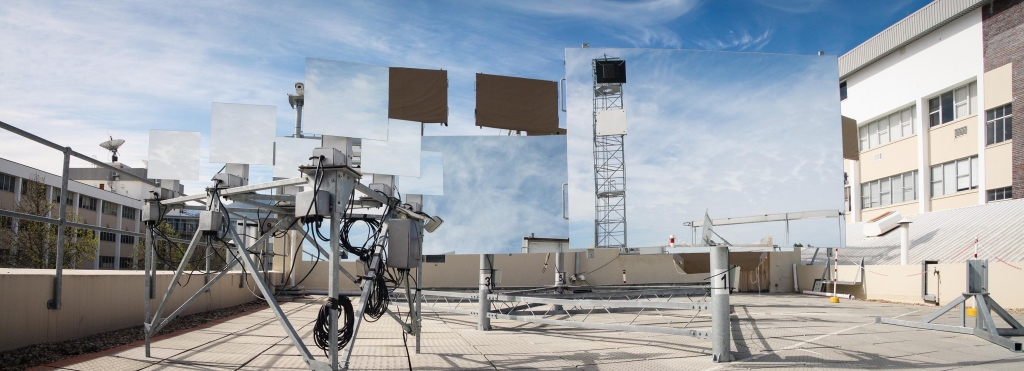

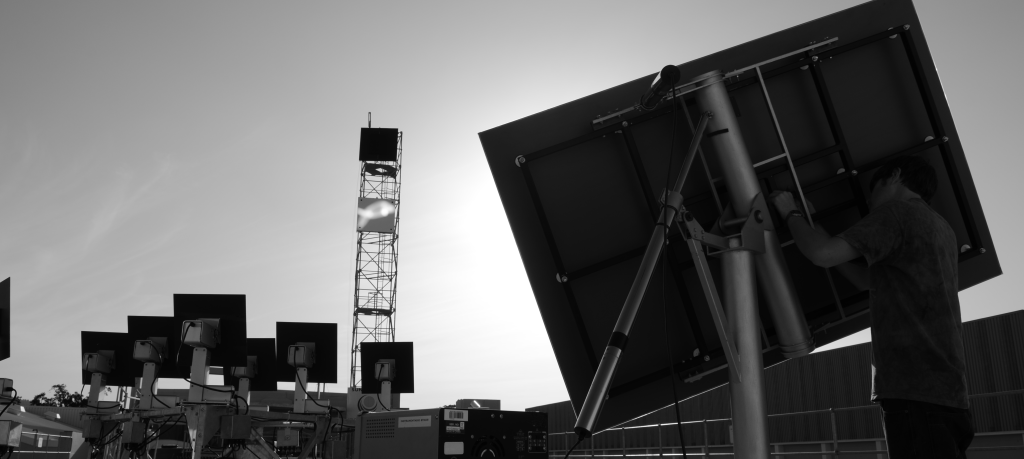

Solar roof laboratory

- 1,000 square meter solar roof laboratory with staff and workshop

- Solar resource assessment and weather station with public website access

- State of the art solar water heater test facility for student research and commercial projects

- 25 kW McDonnel Douglas Sterling dish

- Utilities and control facilities to perform contract R&D on CSP optical systems

Receiver test facility

- 18 m flex use lattice tower

- 40 square meter aperture heliostat field for intermediate flux (~50 suns)

Other research laboratories

STERG owns a number of facilities situated within the Department of Mechanical and Mechatronic Engineering

- 1000 °C Kiln with automated quick charge/discharge capabilities

- 5 cubic meter, 3 ton, 600 °C thermal storage test facility

- Differential Scanning Calorimeter capable of sampling to 700 °C

- Software: Fluent CFD, ArcGIS, TRNSYS, FLOWNEX etc.

- Further access to Departmental heat transfer and flow laboratories including multiple wind tunnel

Stellenbosch University Renewable Energy Centre (SUNREC)

- 2 Hectare facility at Mariendahl experimental farm, enabling dual use of land and cross-discipline research

- Available for SU post graduate students, affiliates and for contract research and testing

- Electrified for multiple experiments including feeding into the grid

- Reticulated water supply

- Fenced for basic security

- Helio100 heliostat R&D pilot system with secure control and storage capable of expansion and adaption. The Helio100 project is closed.

- Full Solys tracker and weather station

- Newly installed 15 kW single axis tracking PV system

- Under construction: Packed bed thermal storage pilot with gas combustor designed to be retro-fitted to an air receiver

MinwaterCSP test facility

A full-scale test facility was purposely designed and constructed at Stellenbosch University to demonstrate the performance of a large diameter axial flow fan under installed conditions and to test and develop the water reticulation system of a deluge condenser cell (see above photo). The facility has the following general specifications:

- 24 ft fan rotor diameter.

- The fan drive consists of a 10:1 parallel shaft reduction gearbox, in turn connected to a 132 kW (rated) electric motor (drive end) and variable speed drive (VSD) for controlling fan rotational speed up to a maximum of 150 rpm. The gearbox and motor are mounted on a slew bearing that enables measurement of the shaft torque.

- The deluge system is quipped with an 18.5 kw pump that enables circulation of water to feed a ¼ quarter segment of a full deluge system.

For more information please visit the following link https://www.minwatercsp.eu/demo-sites/stellenbosch-full-scale-test-facility/