As we turn the page on 2023, we reflect on some of the interesting final year skripsie projects facilitated at STERG this year. Four undergraduate students from the Department of Mechanical and Mechatronic Engineering share highlights from their projects under the supervision of members of staff at STERG.

Performance Testing and Benchmarking of Photovoltaic Thermal Collectors in South Africa

Karl Zapke, BEng (Mechanical) graduate, 2023

Study leader: Prof Michael Owen

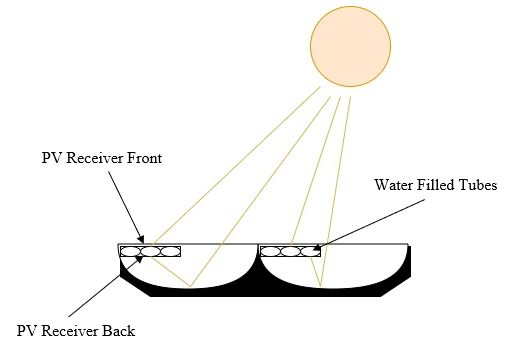

Photovoltaic Thermal (PVT) collectors combine solar thermal and photovoltaic (PV) technologies into a single collector. The working fluid, usually water or air, cools the PV component, increasing its efficiency and generating heated water. These collectors are relatively new to South Africa, and data on their performance in South Africa is scant. This project aimed to gain insight into the performance of a specific PVT collector model by way of experimental tests. The collector, a SOLARUS PowerCollector PC2S, was donated to the university by Greenline Africa.

A testing apparatus was designed, according to the relevant standards, manufactured and used. Results of the tests showed an increase in the thermal efficiency and a decrease in the electrical efficiency of the collector as the mean temperature of the working fluid increased. Benchmarking of the experimental data against standalone solar thermal and PV collectors indicated that the PVT collector performs better than a standalone solar thermal collector, but worse than a PV collector. PVT collectors may thus be preferable for combined heating and electrical power generation applications.

Compact Linear Fresnel Solar Collector

Mathew Brougham-Cook, BEng (Mechanical) graduate, 2023

Study leader: Mr Matthew Meas

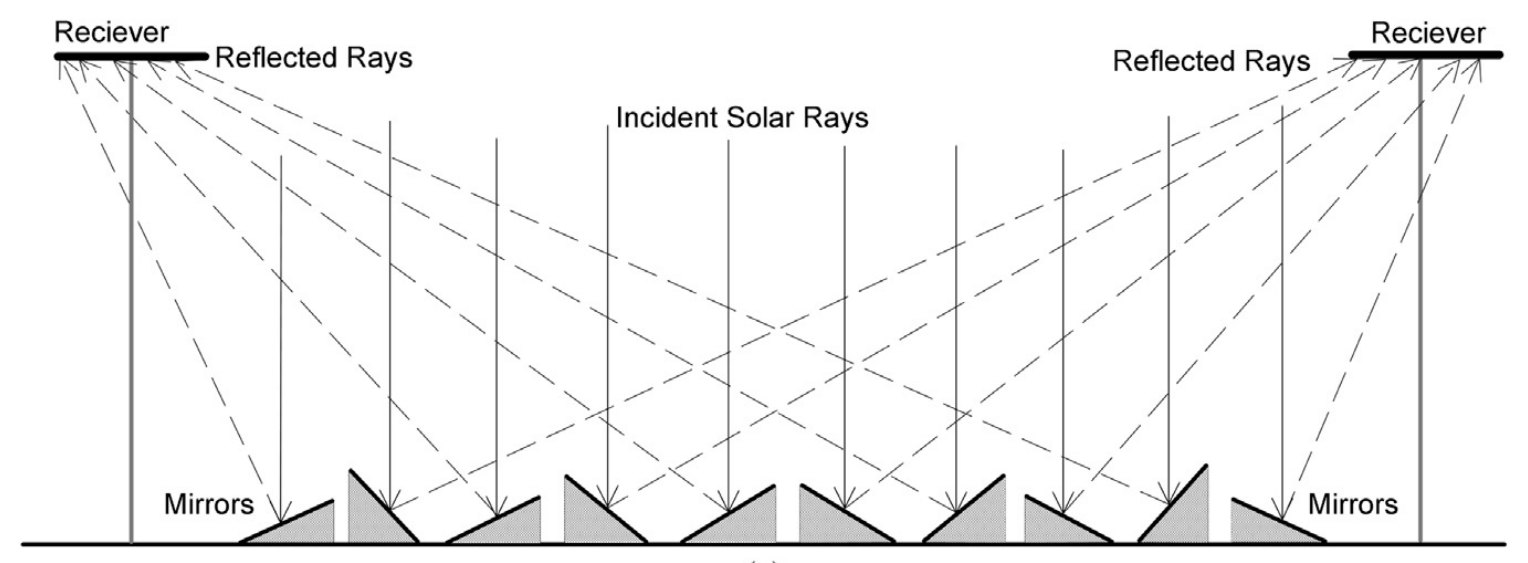

Compact linear Fresnel reflectors (CLFRs) are a relatively new and underexplored linear Fresnel reflector concept in which the reflectors may be independently aimed at one of multiple collector tubes. There is scant evidence of practical implementations of the CLFR design, however, preliminary investigations indicate potential for reductions in blocking and shading, which can reduce system footprint and increase optical efficiency compared to traditional beam-up systems.

A small-scale CLFR system was designed, built, and tested at the solar rooftop laboratory. Various analytical and computational methods were used to develop the array of independently actuated reflectors, the trapezoidal collectors and tubular absorbers, the open loop tracking system, and a support structure, fluid system, and data acquisition system. The system shows promise in terms of its initial thermal efficiency, small (2 m x 2 m x 2 m) footprint and low cost.

The system was designed with adjustability of the reflectors and collectors in mind, to facilitate future alterations and improvements with relative ease. In addition, the cubic form factor was chosen to potentially allow the installation of additional of modules in the future. Ultimately, the project has demonstrated the practicality of the CLFR concept in one of the first successful implementations, with the data acquired adding to the emergent repository.

Thermosiphon Solar Thermal Receiver

Noko Phukubye, BEng (Mechanical) student

Study leader: Prof Craig McGregor

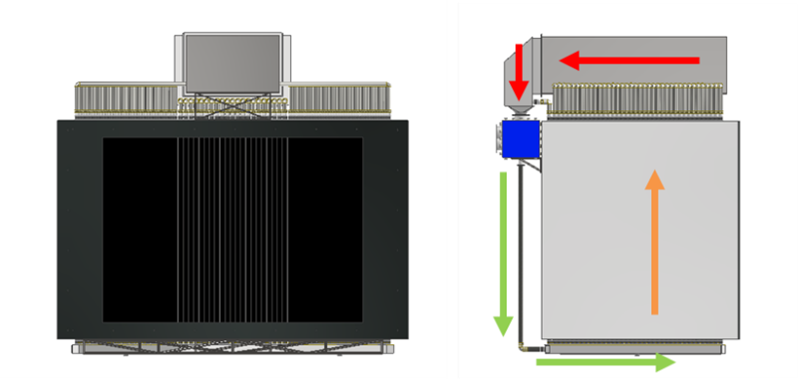

The objective of this project was to contribute to the cost reduction of solar tower power plants through the innovative design of a receiver utilizing a thermosiphon loop with liquid sodium. The use of liquid sodium has enabled higher heat fluxes and working temperatures to be achieved compared to conventional systems, enhancing the efficiency of power plants, and enabling the construction of more compact receivers. Drawing inspiration from the 1 MW DAHAN receiver in China, researchers have a thermosyphon receiver design with a theoretical output of 450 MW.

In this project, a comprehensive mathematical model was developed and used to design a demonstration unit that uses pentane as the working fluid. Once manufactured, the demonstration unit was installed and tested at the solar rooftop laboratory, where formation of a film layer was observed on one of the clear tubes. This observation indicated a balanced boiling-condensation process, affirming the merit and potential of the model for practical application.

Heliostat Wind Load Testing

Dylan Heale, BEng (Mechatronics) graduate, 2023

Study leader: Prof Craig McGregor

This project combined the techniques of modal analysis (impact testing) and wind tunnel testing to examine the frequency response behaviour of a reduced scale heliostat model. Data was gathered using a set of three accelerometers routed through two different data acquisition units to obtain Fourier transforms and frequency response functions prior to further processing and analysis. Following the initial test runs, a tuned mass damper was developed to reduce high amplitude vibrations that were observed at the natural frequencies of the model. A total of 160 test runs were conducted, and the damper was found to successfully reduce the amplitude of these vibrations by up to 61 % in some cases.